Section 1910 28 establishes the employer s duty to provide fall protection for employees on fixed ladders and 1910 29 specifies the criteria for fall protection systems for fixed ladders.

Fixed access ladder inspection.

Figure d 3 example of counterbalanced hatch cover at roof.

As seen in the picture below featuring new ladder system we recommend a wider climbing surface to accommodate a ladder lifeline system and to make the ladder easier to climb.

Note to paragraph d.

However this is not the case.

Fixed ladders walkways and stairs still need inspecting.

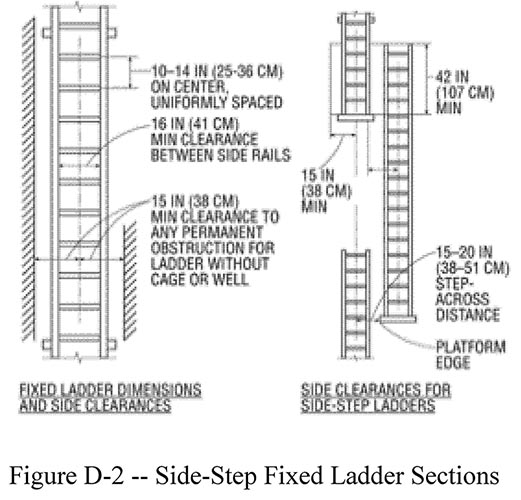

Per osha 1910 23 b 4 ladder rungs steps and cleats have a minimum clear width of 16 inches measured before installation of ladder safety systems for fixed ladders.

Figure d 2 slide step fixed ladder sections.

As is standard with all of our inspections your inspections will be performed via a wireless tablet and data will be uploaded to a secure customer portal for viewing within 24 hours.

Safesite s competent and experienced engineers carry out hundreds of fixed ladder inspections each year across the uk.

We also check the integrity of all support brackets and fixings check whether there is safe access to and onto the ladder and whether warning signs are in place.

Liftsafe technicians are trained and certified to not only inspect but repair all fixed access ladders in accordance with the applicable codes and standards.

For more information about our inspection and recertification service call us on 01293 529977 or use our online contact form.